Complete underfloor heating

The advanced functional principle of underfloor heating:

Underfloor heating uses the entire floor space of a room. This large surface means that you feel the same level of warmth at a much lower temperature than a conventional radiator. Without comprising the warmth felt, the room temperature can thus be reduced by an average of 2°C, directly resulting in energy savings. The small difference in temperature between the floor and ambient air also makes rooms extremely cosy.

The benefits of underfloor heating:

- Great level of comfort thanks to even distribution of warmth

- Air hardly dries out

- Economical as a result of high energy efficiency

- No dust circulation

- Ideal for use with alternative energy systems

- No obtrusive radiators

Easy to lay

with Perotac complete underfloor heating used as an example

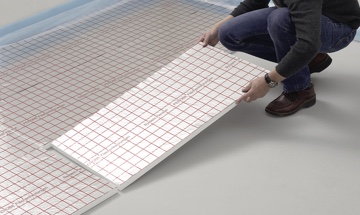

Step 1:

A clean and level surface is always required so that you can lay the aluminium-coated system panels as well as the edge insulation strips.

Step 2:

The system panels are now carefully stuck to one another using aluminium tape.

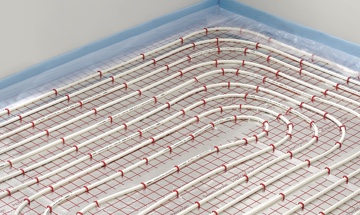

Step 3:

The heating tube is fastened to the system panel using retaining clips. The printed basic grid helps to lay the heating tube.

Step 4:

After connecting the tubes and checking that they are tight, the screed, which must contain an admixture, is applied.

Perobe’s complete underfloor heating systems

PEROTAC wet system

Complete hot-water underfloor heating in a wet design for new buildings

Your benefits:

- Oxygen-diffusion-tight heating tube (DIN 4726), attached to rigid foam panels; enclosed by screed

- Rigid foam insulation panels made of polystyrene (thickness: 30 mm; thermal conductivity group 035)

- Adhesive aluminium foil distributes and transfers heat

- Easy to install; printed basic grid (5 x 5 cm) for straightforward assembly

- For all surface coverings that are suitable for underfloor heating

- Construction height ≥ 9.1 cm

PEROFLEX wet system

Complete hot-water underfloor heating in a wet design for new buildings

Your benefits:

- Oxygen-diffusion-tight heating tube (DIN 4726), attached to rigid foam panels; enclosed by screed

- Rigid foam insulation panels made of polystyrene (thickness: 42 mm; thermal conductivity group 035)

- Grid elements form a closed insulating layer and prevent heat and cold bridges from forming

- Nubs help lay the tube accurately, making for easy installation

- For all surface coverings that are suitable for underfloor heating

- Construction height ≥ 8.7 cm

Perobe dry system

Complete hot-water underfloor heating in a dry design for old and new buildings

Your benefits:

- Oxygen-diffusion-tight heating tube (DIN 4726), embedded in rigid foam panels; can be used with screed or dry screed panels

- Rigid foam insulation panels made of polystyrene (thickness: 30 or 40 mm, grooved, thermal conductivity group 035)

- Covered with galvanised panels for optimal heat distribution and transfer; for stabilising and protecting the tube

- Aluminium-coated grooved panels provide insulation and tube guidance, making for easy installation

- For all surface coverings that are suitable for underfloor heating

- Construction height ≥ 5.5 cm